Get ready to experience the future of telematics.

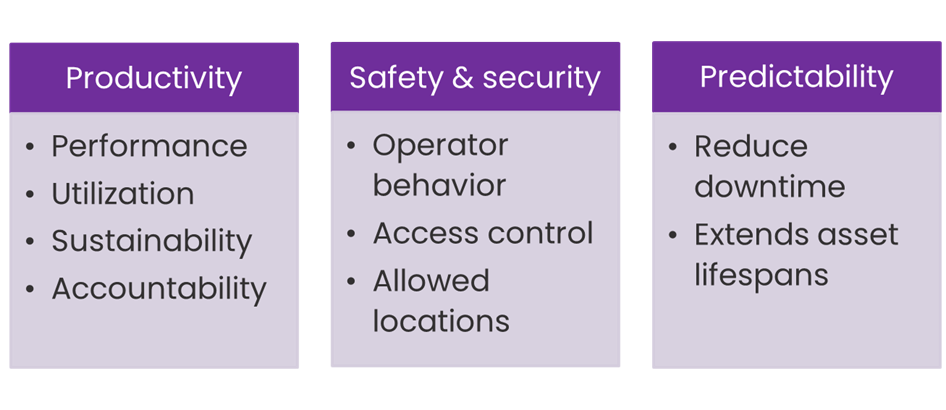

Core features

The T20 is a compact 4G LTE-M IoT device, ideal for tracking and monitoring mobile equipment. Its versatile design, with multiple interfaces and dual CAN bus support, ensures compatibility with various devices and systems. As an LTE-M device, the T20 is future-proof, aligning with 5G specifications.

Configurable Functionality

Aplicom Telematics Application handles typical use cases for tracking and sensor data reading and sending. Application configuration is defined and deployed to the device by using Aplicom Silver Cloud device management cloud service. Deploying units to the field is easy and fast.

Software Development Kit (SDK)

Alternatively, the T20 MicroPython SDK can be used to adapt the device to different needs and do edge data processing. T-Series SDK high level API has all the necessary building blocks for creating custom telematics applications quickly with minimal code.

Data integration

The T20 supports the MQTT protocol, a lightweight messaging protocol ideal for IoT devices. MQTT enables efficient communication between devices and cloud services, simplifying the integration of equipment tracking into existing systems. Using MQTT is a reliable and cost-effective solution for remote monitoring.

For Aplicom A-Series customers we are providing a smooth transition path and support also existing Aplicom D, F and R protocols.

Device Management & Security

As the IoT landscape expands, stringent security regulations like the EU Cybersecurity Act are being implemented to mandate robust security measures for IoT devices, further emphasizing the importance of OTA updates and data encryption.

Aplicom Silver Cloud Device management ensures that T20 devices are up to date with the latest features and removes the need to visit the devices when device configuration needs to be updated. Getting Device Management as a SaaS solution removes the need for investing time and money to build your own OTA service.

Learn more about: T20

Follow us on social media